COVID-19 Boosts Automation in Manufacturing Industry

As nations continue to struggle fighting the coronavirus disease (COVID-19) pandemic, businesses across the globe are also implementing necessary measures to adapt to the new normal and survive its increasing economic and social impact. The manufacturing industry has emerged as an essential sector driven by factors such as a surge in demand for basic products, hygiene and safety, which have resulted in growing discussions concerning the important role of automation across the food and beverage sector.

The trend of automation has witnessed the development of new technologies that are capable of providing fast end-to-end solutions for the production of certain processed foods. In a recent interview, San Miguel Foods president Francisco “Butch” Alejo III emphasized that many industries look at automation for operations under the new normal.

Safety First

Safety is a hot topic in factories and warehouses. Due to the spike in infection, companies were forced to reduce presence of workers across their production processes to help minimize potential contamination. As a way to overcome unprecedented risks, automation can help augment the lack of manpower and help companies cut costs in terms of safety and additional measures for personnel. The use of automated systems can ensure continued manufacturing and supply of food products even with physical distancing in place. In the instance that personnel intervention is needed, automation can help improve process flow and reduce turnaround time for product processing to keep movements of employees at minimum.

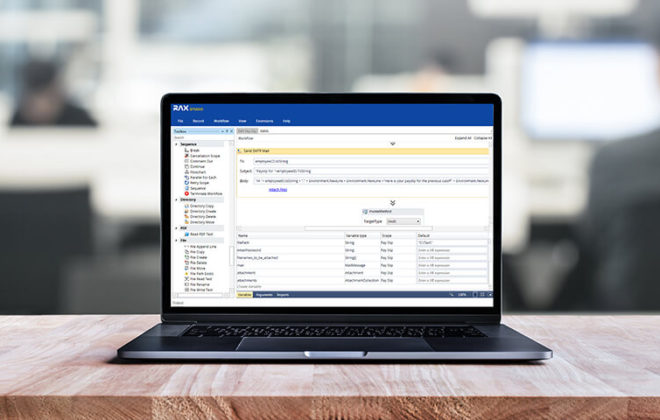

Having robots or automation tools in the middle of an economic crisis does not only protect manufacturers from going downhill but also enhance safety measures for employees. Read here how you can prioritize employee health first through automation.

Improved Raw Material Quality

The function of automation varies based on where it is integrated. Chaitanya Rao and Rinkal Dawra of MarketsandMarkets Inc. noted that there is a growing trend of automation that has resulted in the improvement of raw material quality. In developed regions such as Europe and North America, robots are deployed to take on different purposes such as tray denesters, automatic tray filling units, double lane tramper topseal machines, metal detection or check weighing system, and a product distribution system. Some advanced systems like camera-based sorting, automated washing, peeling, and processing have helped improve the quality of raw materials. As per Rao and Dawra, food manufacturers in the Asia Pacific region are now following the trend of adopting automated systems to stabilize their outputs and reduce costs.

Solving Complex Supply Chain

The disruption in production and shortage in raw materials can be attributed to the adverse effect of COVID-19 lockdown measures to the manufacturing supply chains. The ongoing global outbreak has not just exposed vulnerabilities of supply chains, it brought another unexpected challenge – restrictions on movement led to a rapid change in consumer buying behavior.

To ensure that demands are met, manufacturers need to have a better view of their end-to-end processes from manufacturing to distribution warehouses, and be able to connect between production facilities and logistics operations. Using automation can facilitate this connected environment by making demand predictions, tracking inventory, and dynamically redeploying goods. Jonathan Wright, global head of cognitive process re-engineering at IBM, expects manufacturers to focus on ways to increase automation while ensuring their people are working effectively and collaboratively.

Before the pandemic, automation has already received more investment from manufacturing and logistic fields than any other supply chain technology, as companies aim to cut delivery times and improve overall margins. Moving on, BMW iVentures partner Marcus Behrendt says supply chains will show resilience and that going forward, the concept of decentralized, localized production will come into clearer focus for manufacturing as an industry.

Automate Now

As the COVID-19 continues to bring about uncertainty in the way in which we will live our lives, it is more important now to rethink approaches that ensure both business continuity and employee welfare. The manufacturing sector expects to see a reduction in face-to-face transactions, engage in wider distribution channels, and manage hygiene concerns. The key to recover from this crisis is to focus on how we can best adapt to the post-pandemic era, and automation will be a critical component in this trend.